Mission

To redefine the standards of manufacturing excellence by providing unparalleled flexibility, automation, and reliability to our partners. We are committed to empowering businesses of all sizes to thrive by offering transparent pricing, scalable production solutions, and innovative technologies. Through our relentless dedication to innovation, efficiency, and customer satisfaction, we aim to be the trusted strategic partner that drives our clients' success and fuels innovation in every industry we serve.

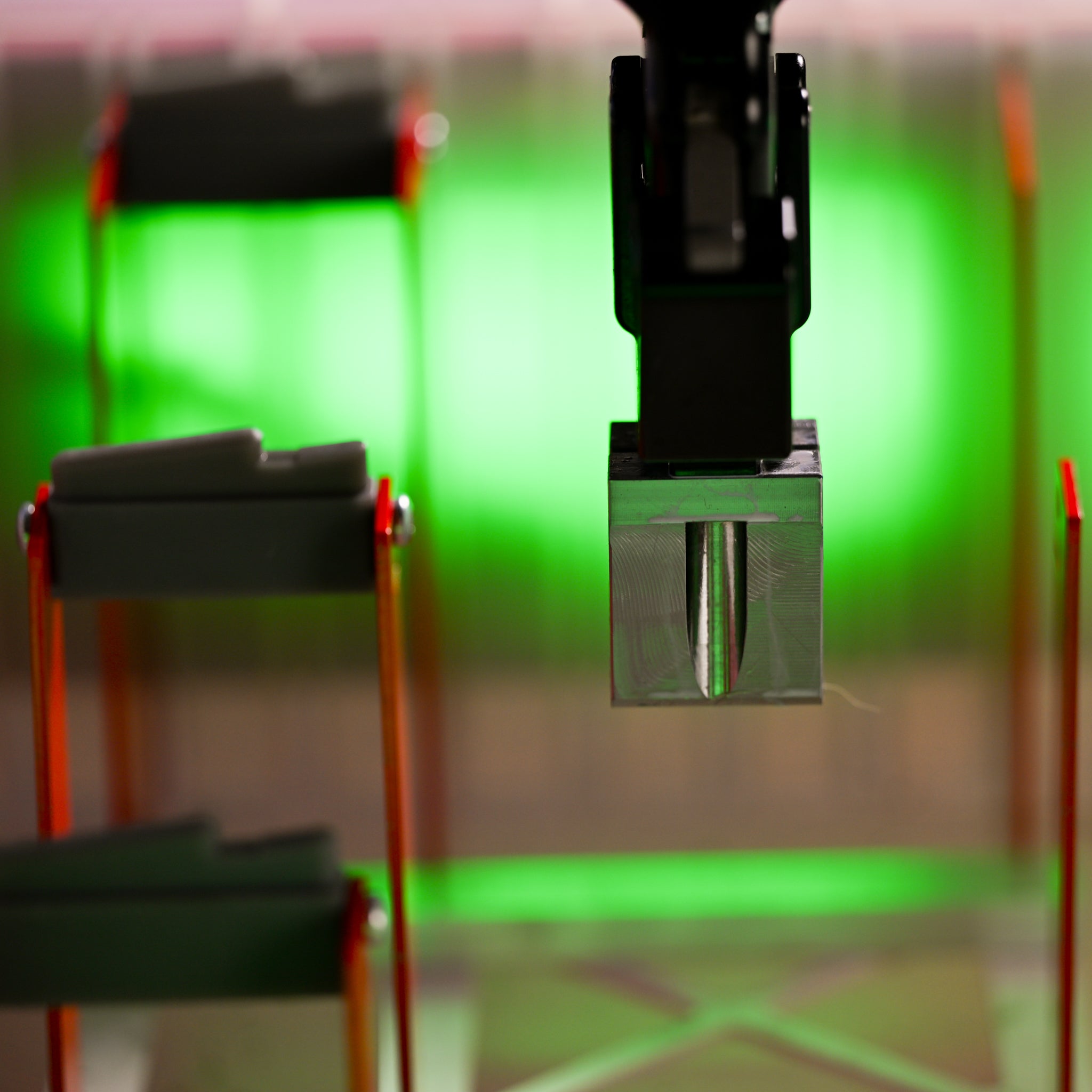

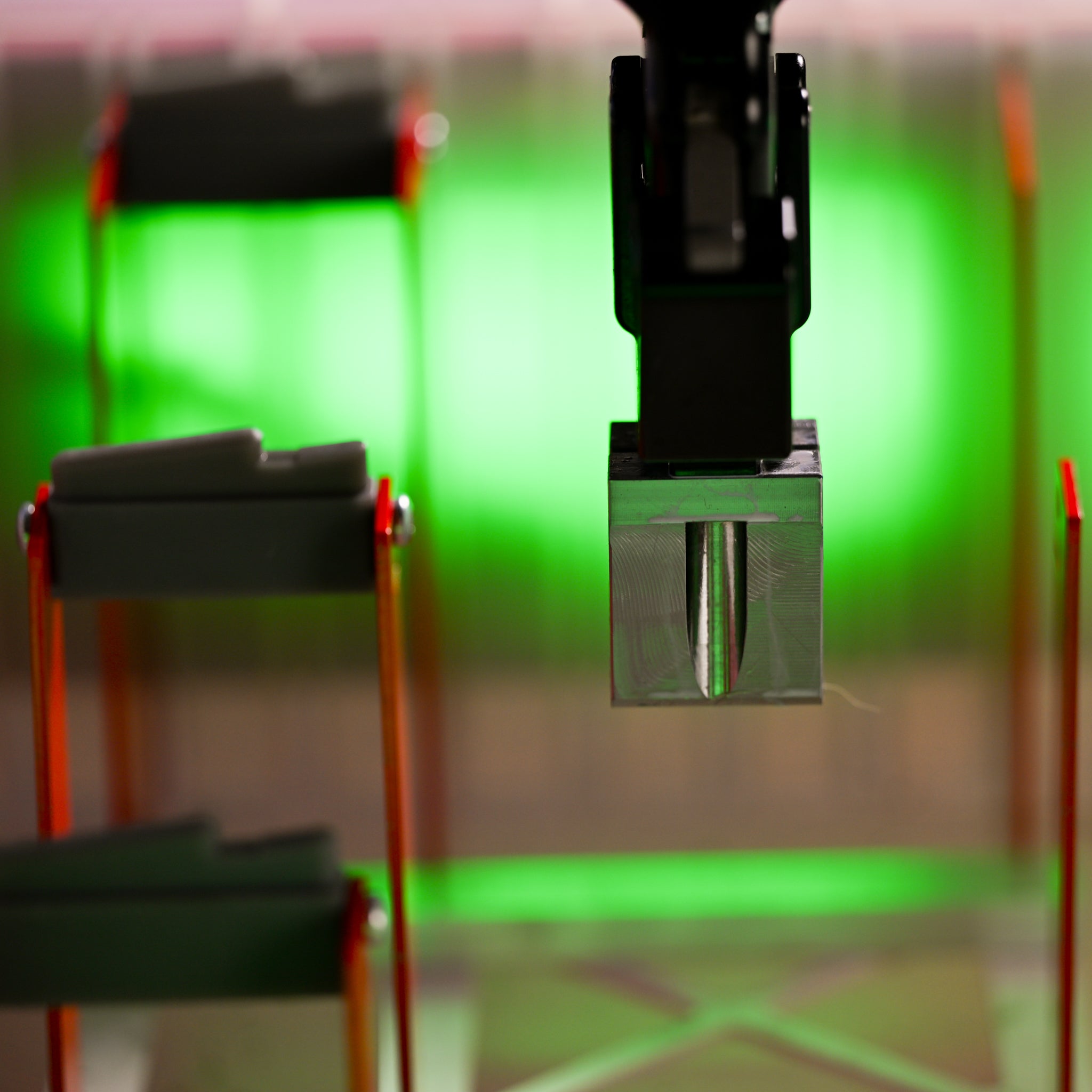

Reliability

The primary focus of our APC development and manufacturing teams, reliability is a staple of any effective production system and process.

We believe true reliability is often a reflection of simplicity; instead of layering on unneeded movements, unnecessary sensors, and complex setup processes, we instead embrace a fanatical focus on simplicity. Simple solutions tend to be the most complex during development, but continue to pay dividends long after they enter use.

By using statistical process control as a fundamental metric, we're able to focus on what matters without anecdote and noise. When paired with a militant-esque approach of root-cause problem solving, this data pushes us to innovate far beyond what is traditionally tolerated in the industry, and provides clear and unbiased data staking our claim.

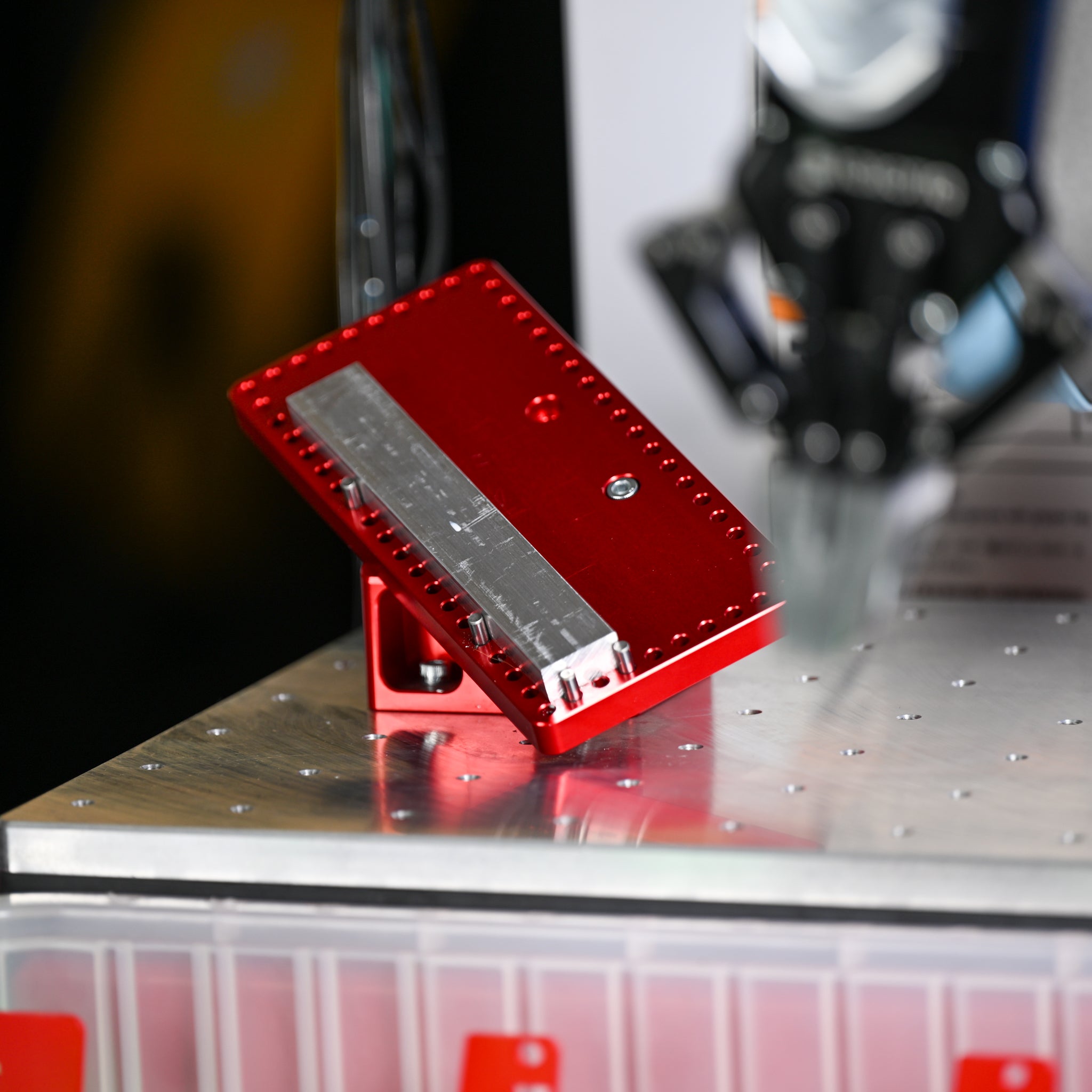

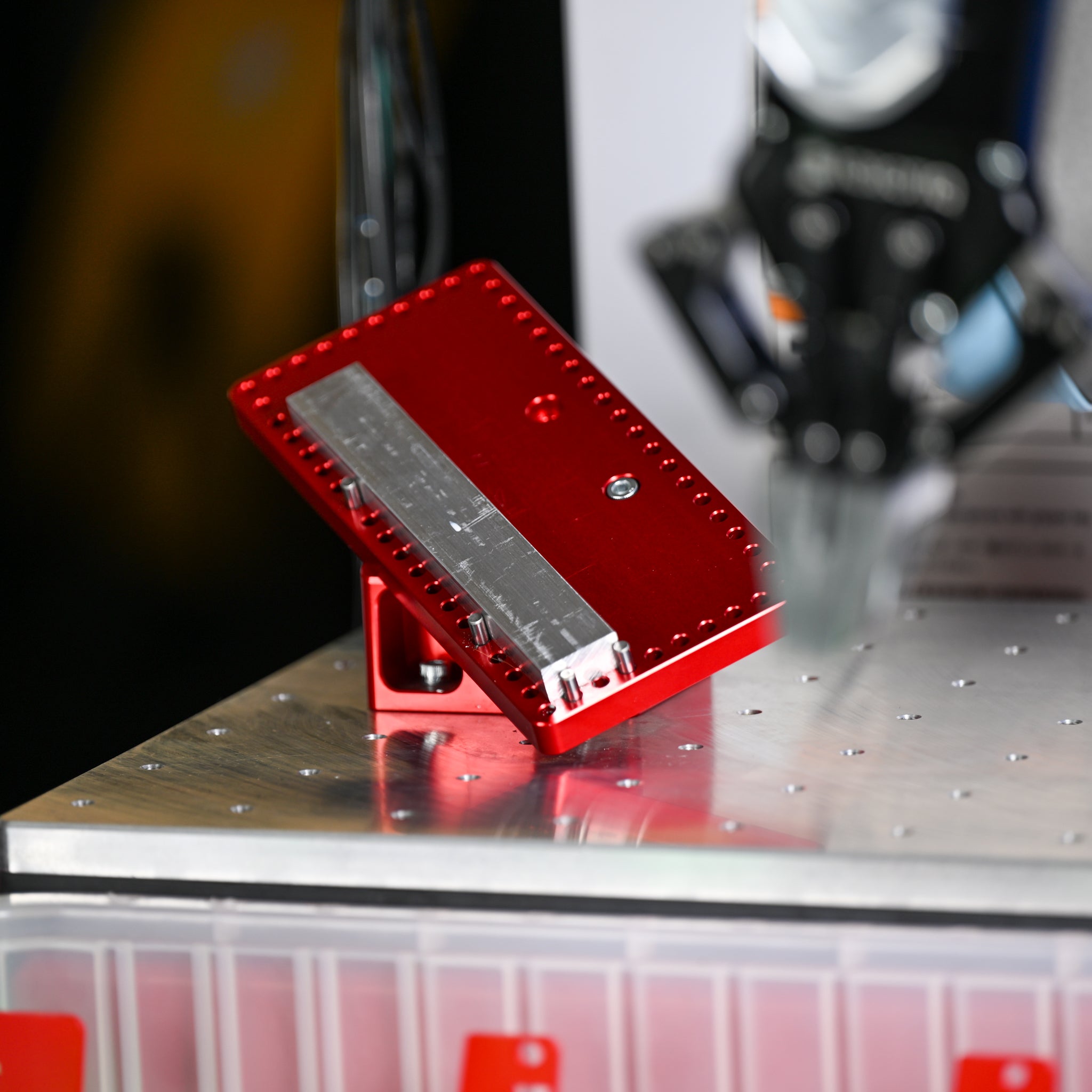

Fexibility

Flexibility and automation have traditionally had a relationship similar to oil and water. We believe automation without flexibility has a similar usefulness too.

Any component that is suitable to the Process and Volume of an APC is easily produced. Automation is no longer a barrier to rapid innovation, improvement, or the growth and diversification of your business.

True flexibility starts with onboarding a new part and process, and we strive to reduce the time to create a "recipe", a new unique process and part, to zero. Flexibility continues with daily-mix, which we define as "changeover". You've likely guessed by now, but we also believe changeover time should be reduced to zero.

Automation

We define automation as the amount of human participation required to put material in, and get parts out.

We believe human participation should be shifted towards intrinsically fulfilling, high-value effort, and automation simply serves to multiply their efforts in these areas. Systematically removing low-value repetition reduces the statistical opportunity for errors that can harm your team, timelines, and equipment.

Quantitatively, we define this by human minutes per hour of machine operation, with a goal of zero.

We don't believe effective automated processes require a human to watch it work, or repetitively load and unload individual operations.

Mission

To redefine the standards of manufacturing excellence by providing unparalleled flexibility, automation, and reliability to our partners. We are committed to empowering businesses of all sizes to thrive by offering transparent pricing, scalable production solutions, and innovative technologies. Through our relentless dedication to innovation, efficiency, and customer satisfaction, we aim to be the trusted strategic partner that drives our clients' success and fuels innovation in every industry we serve.

Reliability

The primary focus of our APC development and manufacturing teams, reliability is a staple of any effective production system and process.

We believe true reliability is often a reflection of simplicity; instead of layering on unneeded movements, unnecessary sensors, and complex setup processes, we instead embrace a fanatical focus on simplicity. Simple solutions tend to be the most complex during development, but continue to pay dividends long after they enter use.

By using statistical process control as a fundamental metric, we're able to focus on what matters without anecdote and noise. When paired with a militant-esque approach of root-cause problem solving, this data pushes us to innovate far beyond what is traditionally tolerated in the industry, and provides clear and unbiased data staking our claim.

Fexibility

Flexibility and automation have traditionally had a relationship similar to oil and water. We believe automation without flexibility has a similar usefulness too.

Any component that is suitable to the Process and Volume of an APC is easily produced. Automation is no longer a barrier to rapid innovation, improvement, or the growth and diversification of your business.

True flexibility starts with onboarding a new part and process, and we strive to reduce the time to create a "recipe", a new unique process and part, to zero. Flexibility continues with daily-mix, which we define as "changeover". You've likely guessed by now, but we also believe changeover time should be reduced to zero.

Automation

We define automation as the amount of human participation required to put material in, and get parts out.

We believe human participation should be shifted towards intrinsically fulfilling, high-value effort, and automation simply serves to multiply their efforts in these areas. Systematically removing low-value repetition reduces the statistical opportunity for errors that can harm your team, timelines, and equipment.

Quantitatively, we define this by human minutes per hour of machine operation, with a goal of zero.

We don't believe effective automated processes require a human to watch it work, or repetitively load and unload individual operations.

Sustainable

Reducing waste is the core concept behind Lean Principles. We see waste as:

- Scrapped Raw Materials - a finite resource on earth

- Human Time - a finite resource where a focus on productivity provides a greater balance of time for truly human conditions (self-friends-family)

- Machine & Production Time - lost time is lost money, and money is the great equalizer. Less financial waste means more opportunity, with less resource consumption.

Recycling - Even with fanatical focus on waste reduction; scrap happens. Where scrap exists, recycle.

We design products to last lifetimes, poised for continuous improvement rather than obsoletion. Modular designs are easily serviceable and user-upgradeable. Our Software is expansive and ever improving - and always offered remotely to our customers. Packaging is minimalistic and fully recyclable.

Scalable

APC development, associated best practices and processes are intentionally systematized, such that our community can share in that value. We continue to build resources beyond our core products, to support the growth of our customers and their experience.

We believe in the strength of Community - We grow with our employees, partners, customers, and vendors.

Distributed

Supporting manufacturing startups and re-shoring endeavors by offering contract manufacturing services that leverage our APCs, thereby reducing the barrier to entry and cost of early phase growth. As these startups or small business grow, they have access to the tools (APC's) to help them vertically integrate completes our goals to see a more distributed independently owned manufacturing landscape.

With manufacturing distributed; goods and products are fulfilled over shorter distances, can be improved and adapt to market demands with more agility, and distribute economic value across our nation.