The ORIGINS

Bottom Up Automation - Wiley Davis's Story

Success Creates a Trap

Coming down Teton pass the truck fishtailed as I did everything I could to keep us out of the ditch. In the bed of the truck sat the disassembled components of a CNC machine I’d just purchased to launch my new business, Hondo Garage. Now all I had to do was get it home safely.

I got the machine home, designed a product, launched a kickstarter project, and Hondo Garage was born. But as sales grew, I was trapped in a quagmire of my own success. The machines became my master and the pressure to always be pressing buttons and swapping parts became a fixture in my life. No time to design new products, no time to work on the business. Employees helped here but hiring employees as a startup is nerve-wracking. Sales would spike and then shrink. With no historical data to project a light into the future, the decision to hire more people or buy more machines felt akin to a spin of the roulette wheel. But then one day, I saw an ad for a Universal Robots arm. And an idea for a way out of this mess began to form.

Robots Offer a Way Out

Automating the machine tending was an obvious solution. But an initial foray into the world of integrators quickly showed how difficult automating can be if you require flexibility and reliability. Integrators would happily build you a reliable system for one part. Trouble was, we had dozens of parts and we were constantly improving their designs. And the few “flexible” systems on the market were anything but. To have any benefit at all, you have to be able to walk away from the machine and trust that it will run.

So when we got our first robot at Hondo Garage, we didn’t hire an integrator. Instead we rolled up our sleeves and started solving the problem in a bottom-up fashion. We needed day-in day-out reliability and the ability to onboard new parts quickly... something the integrators couldn’t promise.

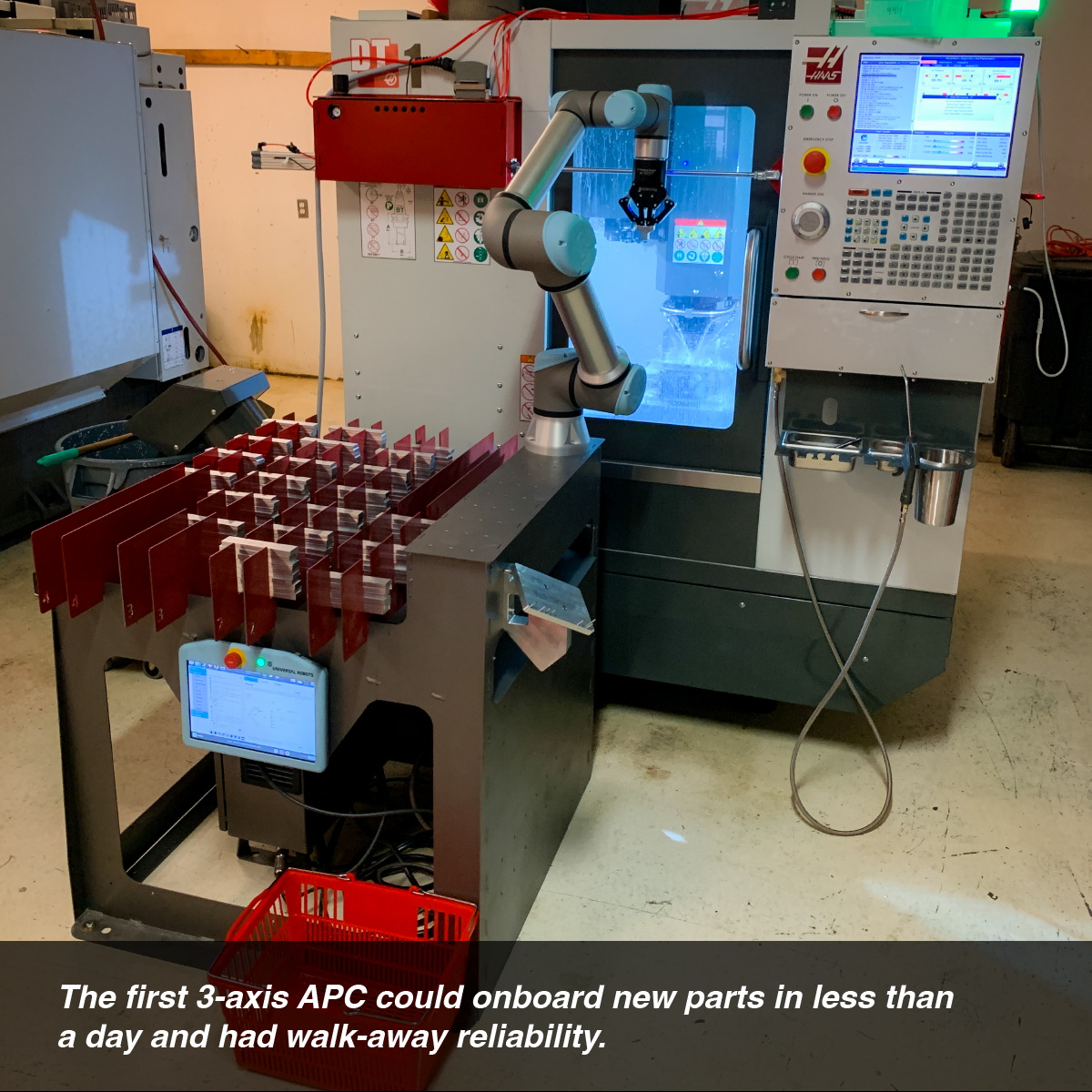

The First APC

After years of refinement, we finally arrived at what we consider to be our first APC, a system that truly delivered on the dream of reliability and flexibility. We built a standardized process capable of making any complete 3-axis milled part (or multiple parts) that fit within a certain volume. Our APC could hold enough material to run an unattended night shift, and we could onboard a new part in less than a day, and walk away from it with confidence that same day. And we’d come back to complete parts, as our system confidently handled the dreaded op1 to op 2 part flip.

The secret sauce for reliable flexibility is a deep understanding of the tiny little details involved in the machining process, honed to clarity in the pressure cooker of daily production demands.

Scaling the APC Concept

In late 2017 I began scheming on a bigger project that would put the APC concept to the test. The idea was a new kind of rugged pop-up truck camper that would be both affordable and built from a large number of high-quality machined components. After some initial prototyping, I launched Go Fast Campers in 2018. GFC quickly grew from a small team of three people in a tiny shop to a sprawling manufacturing campus, becoming the largest manufacturer of popup wedge campers along the way.

GFC manufactures campers to order with over 200 unique models and a daily production mix driven by order demand... a powerful capability made possible by the Reliable/Flexible performance of our APC concept.

Taking the APC To Market

Eight years of R&D and two successful product manufacturing businesses worth of experience baked into the design, software, and operation - now for the future of manufacturing.

We know how hard it is to launch and grow a small product company, and we want nothing more than to help you. Machined parts on demand, managed kanban inventory, and transparent data all to help you focus on your customer, while not distancing yourself from manufacturing.

Now when it's time to grow or adapt to a changing economic landscape, it's time to invest in your automated manufacturing verticals. We are here, ready to commission your first APC or a fleet.

We will continue to innovate, support and contribute to this cause; it's our promise.